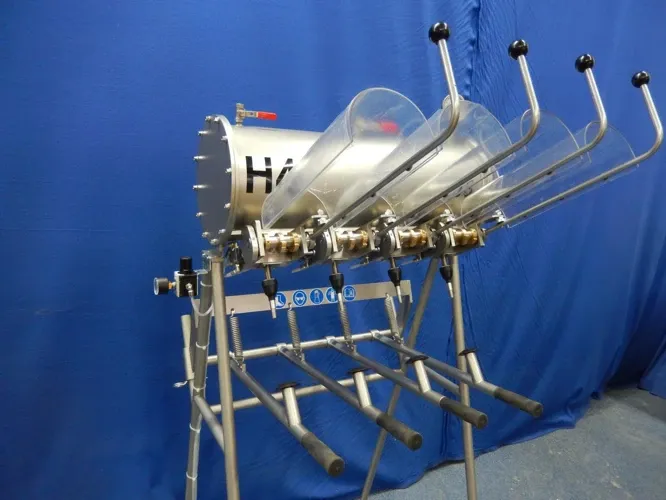

Semi-automatic bottle filling machine for 0.33 – 1 or 2 L bottles

6 head filler H4 - with CO2 flushing of the bottles

Cleaning up to 130°C (steamable)

Capacity: up to 300 bph with 0.5 l bottles

Semi-automatic bottle filling machine H4

The filler has 2 - 8 filling heads, all of which can be adapted for syphon bottles on request can.

It consists of a pressure vessel, pressure gauge, float switch, volume indicator, inlet tap, drain tap and connection tap for CO². The filling line works on the basis of pressure equalization. The pressure vessel is preloaded to the desired filling pressure via the connection tap for CO². The beer line is connected to the inlet tap, whereby the inlet pressure must correspond to at least the same pressure as the desired filling pressure. After opening the beer supply line, carefully open the drain tap from the float switch. By escaping the existing pressure, the beer can slowly flow into the pressure vessel. This can be observed on the volume indicator. Once the beer has reached its maximum volume in the pressure tank, the float switch closes the vent valve automatically. The filling of the bottles can begin.

A) Filler up to 65°C

You insert a bottle between the filling nozzle and the holding arm. Then press the filling lever about 10 - 15 cm before the full stop, wait about 1-2 seconds and then push the filling lever all the way down. In the first position, the bottle is preloaded with CO² and in the final position, the bottle is filled. Once filled, the filling lever is lifted back to the top.

B) Filler up to 130°C (CO² rinsing/rinsing)

You insert a bottle between the filling nozzle and the holding arm. Then push the filler lever down. In the first snap-in position, the bottle is flushed with CO² via an external CO² connection. This reduces the O² content in the bottle. After the desired CO² flushing time (2-3 seconds), the lever is moved one position further. In this position, the final pressure equalization with the filler tank takes place. The bottle is preloaded with CO² from the filler tank and the bottle is filled in the final position. Once filled, the filling lever is lifted back to the top.

Wait about 2 seconds until the excess pressure in the bottle can escape via a drain valve in the filling nozzle. Then remove the filled bottle from the filling station and close it. Optimal filling is achieved by a beer cooled to 0°C - 2°C with a filling pressure of 1.5 - 2 bar.

IMPORTANT ! ! !

After completion of production, the entire system must be rinsed with hot water (40°C) or a cleaning agent. It is essential to ensure that the vent valve of the filling nozzle is cleaned optimally, otherwise it will not be possible to fill properly the next day.

ATTENTION ! ! !

Only one operator may stand at the filling machine and operate it. During the filling of the bottles, under no circumstances should they be gripped under the protective hood or on the bottles to be filled, as an explosion of the bottles cannot be ruled out and there is therefore a risk of injury. If you want to realign the bottle for any reason, the filling lever with protective shield must be pushed upwards so that the bottle is no longer under pressure. After aligning the bottle, the filling process can be started again.

When converting for the filling of bottles from 1 liter to max. 2 liters and syphon bottles, there is an additional price of 366, - € / filling point

| Length | 800 | mm |

| Capacity | 0 | L |

| Width | 1200 | mm |

| Total heigth | 1700 | mm |