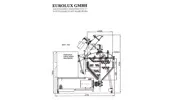

Eurolux-BAV Vacuum-processing system Type A-400

For ketchup, mayonnaise, dressing, mustard

(without storage container - at an additional cost)

Semi-automatic / fully automatic

Performance depending on the process technology

NEW / as good as new

Eurolux-BAV Vacuum-processing system

UNI 167-446

Container capacity: 400 liters

Batch size: 100 - 330 liters

Cold production: output approx. 3-4 batches / hour.

Pressure resistance: vacuum-proof -1 bar / + 1.5 bar

Bottom design: cone

Tank inlet: DN 65 right-angled, left (threaded connector DIN 11851)

Container outlet: DN 125 (flange firmly screwed)

Pressure relief valve: DN 25

Product area: food

Product contact: V4A AISI 316 (1.4571)

Surface quality: sanded, grain 240

Seal quality: EPDM

Extras / surcharge: 1) Kieselmann valves, surcharge depending on the

type of equipment, see price list

Fittings: DIN 11851

Operation voltage: 400 volts, 50HZ, 3 phases N, P, PE

Control voltage: 24V DC

Air connection: ¼ “5-6 bar

Homogenizer: type Eurolux 22 kW 3000 RPM

Vacuum system: 1.5 kW

Agitator: 2.3 kW 10-40 rpm

Inlet nozzle right: DN 50

Inlet nozzle left: DN 50

Floor drains: 2 pieces DN 50

hand flaps with blind caps

Residual drain: DN 50 with disc valve and blind cap

Connection on the pressure side: DN 65 threaded nozzle DIN 11851

Connection suction side: DN 120 flange screwed

Homogenizer inlets mixing chamber

Rotor: 10 x 15 mm

Stator: 30 x 4 mm

Connection left: DN 50 disc valve

Connection on the right: DN 50 disc valve

Direct dosing water: DN 40

Direct Dosing Oil: DN 40

Bottom flow: DN 50 disc valve for CIP return

Main drive

Design: three-phase motor

Power: 22 kW

Rated speed: 2960 rpm

Protection: IP 54

Insulating material class: B

Shaft seal: GLRD / single-acting

Double sheath mixing container:

Double sheath: max.3 bar

Insulation sheath: 50 mm rock wool for heating or cooling with steam

or water, etc. without valve

Lid

Seal design: Profile seal (standard) EPDM

Pressure resistance: vacuum-resistant - 1 bar

Lid: 1 sight glass NW 125 with wiper and lamp, 3 supports for CIP nozzles

Lid lifting device:

Extras / surcharge: 2) Lid lifting device,

surcharge depending on the

type of equipment, see price list

Mixer

Type: Scrape stirrer with flow breaker

Scraper: PTFE

Agitator motor

Type: Three-phase geared motor AISI 304

Power: 2.3 kW

Output speed: 10 - 40 rpm adjustable right/left-hand run

Protection: IP 54

Insulating material class: B

Painting: RAL 1013 (Pearl White)

Seal: Garlock shaft seal

Nominal size: DN 32

Pipe connections: DIN 11851

Seal quality: EPDM

Extras / surcharge: 2) Vacuum regulation

surcharge depending on the type of equipment, see price list

Pressure sensor: E + H

Control voltage: 24 V DC

Measuring range: -1 / +1.5 bar

Vacuum shut-off valve: ball check valve

Vacuum pump: water ring pump

Power: 1.5 kW

Protection class: IP 54

Insulation class: F

Maintenance unit: water control device (24V DC)

Voltage: 400V, 50Hz

Extras/ surcharges: 4) Oil Vacuum pump (low noise)

surcharge depending on the type of equipment, see price list

Re- circulation line

Pipe size: DN 65

Discharge line: DN 65 perpendicular to the mixing tank

Discharge line: DN 65 with discharge elbow at a height of approx. 165 cm

Base frame and platform

Raw frame: with cover plates

Material: V2A AISI 304 (1.4301)

Dimensions: L = 2000 mm, W = 1200 mm, H = 2200 mm

Foot design: machine feet adjustable in height

Surface treatment: glass beads blasted

Extras/ surcharges: 5) Tank 1

surcharge depending on the type of equipment, see price list

Material: AISI 316 (1.4571) Weight: 35 kg

Volume: 150 liters

Outlet: butterfly valve DN 50

Bottom design: cone

Surface quality: ground to grain 240

Attachment: on three feet

Connection line: DN 50 with hand flap

Function: Sucking in the dry matter components via vacuum

Extras/ surcharges: 6) Tank 2

surcharge depending on the type of equipment, see price list

Material: AISI 316 (1.4571) Weight: 20 kg

Volume: 100 liters

Outlet: butterfly valve DN 50

Bottom design: cone

Surface quality: ground to grain 240

Attachment: on three feet

Connection line: DN 50 with hand flap

Function: Sucking in the dry matter components via vacuum

Without scales, display, electronic connection and software.

Automatic dosing of water in homogenizer

Manuel inlet

Extras/ surcharges: 7) Dosing

surcharge depending on the type of equipment, see price list

Fully automatic dosing of a preset amount of water

via IDM (Endress + Hauser)

Automatic dosing of oil in homogenizer Dosing of oil into the homogenizer

Cleaning CIP

Extras/ surcharges: 8) CIP Nozzle for cleaning the system

surcharge depending on the type of equipment, see price list

3 CIP nozzles with CIP rotating nozzles, pneumatic valves and pipe

connections to the automatic cleaning process of the system (Lechler)

Electric control standard on / off

Control cabinet: built on the platform of the machine

Protection class: IP 54

Material: AISI 304 stainless steel

Extras / surcharge: 9) Electric control surcharge depending on the type of equipment,

see price list

Execution: Siemens PLC control Operation: via color touch panel 19 "

Price List:

|

|

|

|

|

A400 Basis price |

|

|

|

2 pieces Price on request |

16 pieces Included! |

|

Price on request |

Price on request |

|

Price on request |

Included! |

|

Price on request |

Price on request |

|

Price on request |

Price on request |

|

Price on request |

Price on request |

|

Without |

Price on request |

|

Price on request |

Price on request |

|

Price on request |

Price on request |

|

included |

included |

|

Net Item 1 – 10. |

Price on request |

Price on request |

|

Price on request |

Price on request |

The above price does not take into account any training or program changes (connection of additional devices).

Our prices are net, plus VAT, ex works D-97753 Karlstadt, freight cost share,

according to scope of delivery,

subject to prior sale and price changes

The delivery and business conditions listed on our homepage apply.

| Weight | 1600 | kg |

| Length | 2000 | mm |

| Capacity | 400 | L |

| Material | V4A (AISI 316) 1.4571 | |

| Width | 1200 | mm |

| Total heigth | 2200 | mm |